One of the many global challenges around regulatory requirements is to find new methods to minimize degrading antimicrobials, or as some refer to as preservatives. As more legislation is put into place requiring the lowering of antimicrobials in various formulations, the actual preservation of the preservative becomes important. Also, more stringent industrial hygiene is also required so that the workload of the antimicrobials is reduced.

Today there is a large amount of work being conducted in the antimicrobial space and we can assist in any number of ways. We are working with a major supplier of reducers to understand the impact of REDOX systems on the degradation of common preservatives, specifically CMIT and MIT (5-Chloro-2-Methyl-2H-Isothiazol-3-one and 2-Methyl-2HIsothiazol-3-one) type preservatives. Using common xxxx and more sophisticated analysis such as HPLC/DAD, we can precisely determine preservative degradation rates and amounts.

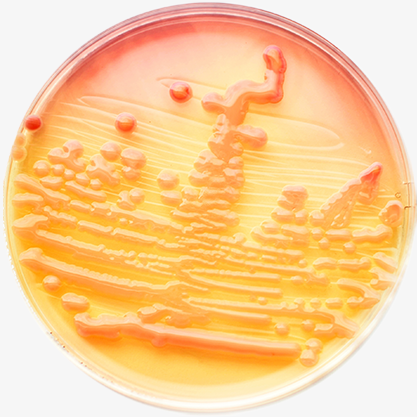

Our scientists are studied in this area and work on a number of fronts. Microorganisms have simple growth requirements which are easily met in today’s manufacturing environments related to coatings. Biocides are used extensively in the manufacture of raw materials and paints. Dry film fungicides are added to formulations to inhibit mold and mildew growth once they are applied. Given all these various uses, we have the experience and expertise to help you with any solution.

We perform various types of microbial testing for yeast, Bacterias and mold. We also will visit your industrial facilities to audit and provide an appropriate hygiene plan to help mitigate issues in the future.